The new anti-bi-metal polyamide is the result of the partnership established between Extrusal and Tecnoform, and it’s the most recent innovation presented for hinged door solutions. A solution that reinforces the correct functioning of the closing of the interior profile of the doors, eliminating the recurring bi-metal effect.

Extrusal is one of the main players of aluminium solutions for architecture and offers window and door systems (hinging and sliding); coating, cladding, and shading solutions; balustrading systems and indoor solutions. With a proactive attitude in sustainability, Extrusal has been focused, for over 50 years, on developing sustainable and durable solutions that guarantee the comfort of buildings. Aware of this importance, Extrusal teamed up with Technoform, a world leader in the extrusion sector of polyamide 6.6 reinforced with fiberglass. Together, they share a common vision of driving the provision of a final solution that exceeds market expectations.

A.055 Extrusal Door System

The new anti-bi-metal polyamide was developed for the A.055 door system with thermal break. A.055 is a hinged door system for the construction of large dimensions and for intensive use: the sash can have a maximum width of 3000 mm and a height of up to 1200 mm. It is a system that presents different opening types: side-hung opening to the inside/outside, swing opening and pivoting (on vertical axis).

To guarantee the durability of the solution, Extrusal, in collaboration with Technoform, developed a new polyamide 6.6 with fiberglass that enhances the correct functioning of the sashes, reducing opening problems caused by the usual bi-metal effect. The new polyamide was introduced in all openings typologies of the A.055 system.

The bi-metal effect, which results from the high temperature difference between the interior and exterior aluminium profiles of a window/door, is a very common factor in climatic areas, where frames are exposed to high levels of solar radiation.

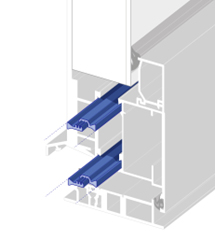

The new polyamide introduced in the A.055 system allows the expansion of the outer aluminium profile without affecting the closure of the inner profile, thus allowing correct opening/closing operation.

The polyamide thermal break profiles are designed to slide together, allowing the exterior and interior aluminium profiles to expand independently.

Benefits of the new anti-bi-metal polyamide

The product not only meets the need to improve the correct opening mechanism of the A.055 system, but also offers other distinct benefits, both for construction professionals and users:

- Reinforces the thermal insulation of the A.055 system;

- Optimization of system operation – allows the expansion of the frame profiles;

- More economical solution than the previous alternative;

- Handling identical to any Technoform standard reference;

- Possibility of replacing existing rods without modifying the assembly process.

Essay

The new anti-bi-metal polyamide was subjected to the following tests:

- Transverse tensile strength test in accordance with EN 14024.

- Measurement of deformation in a window in accordance with EN 13420: behavior between different environments. Test Method.

- Measurement of operating forces in accordance with EN 12046.

The partnership established between Extrusal and Technoform allowed the development of an innovative solution with extraordinary results, always guaranteeing the aesthetics of the system. This product reinforces the importance of usability and correct functioning of all elements of a window/door for sustainable construction: durability and optimization of thermal performance.

This collaboration is not an isolated story, but rather a stimulus for future innovations. Both companies are committed to continuing this collaboration, exploring new opportunities and tackling emerging challenges. The joint vision is to shape the future of the sector and provide construction professionals and users with products that exceed their expectations.